|

|

Friday, May 22nd, 2020

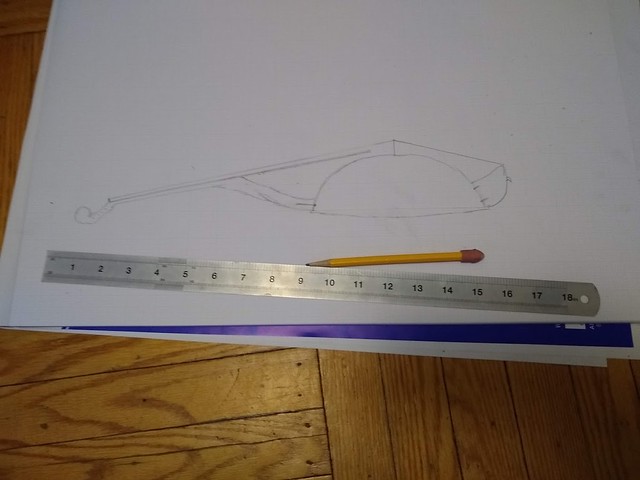

Here is how the two-piece neck is shaped --

Next step is cutting the mortise in the upper neck and finalizing the length!

posted afternoon of May 22nd, 2020: Respond

➳ More posts about Projects

|  |

Thursday, May 21st, 2020

Today I did a first rough fit of the tailpiece and neck into the viola d'ottone. I'm overjoyed to see everything lining up straight, I was quite convinced there would be a misalignment that I'd have to correct for.

posted evening of May 21st, 2020: Respond

➳ More posts about Luthery

|  |

Tuesday, April 28th, 2020

I think I need to laminate the brass viola's neck out of two pieces, so the grain in the upper neck and pegbox/scroll can be straight. I do not think it will be strong enough going at an angle across the grain as it is currently laid out [cf]. I have a pretty clear mental picture of what the joint should look like.

posted morning of April 28th, 2020: 1 response

|  |

Monday, April 27th, 2020

I've laid out the neck for my brass viola. Next step will be cutting the outline and the tenon. I will leave the full thickness of the board in place until the neck fits into the viola body straight and lined up with the tail.

posted morning of April 27th, 2020: Respond

|  |

Saturday, February first, 2020

In my post below on dowel vs. bolts I've been working through a couple of different designs for the brass viola. A dowel will absorb most of the tension of the strings, so that the tension on the soundboard is primarily from the bridge pressing down towards the dowel. If instead of a through dowel, I use blocks and tenons at either side of the pan, then it seems clear there will be a lot more tension on the pan, and in different directions. The question in my mind is whether this extra tension will enhance the sound or detract from it.

My guess is that the extra tension across the soundboard will be a good thing, is why I'm leaning toward the latter solution. You need tension for the soundboard to resonate; so why not add more tension? As I visualize the instrument strung up, the strings would tend to pull the endpin upwards, which would in turn pull the tail block against the pan, this would have the effect of making the pan quite taut along its length. If the instrument were constructed with a dowel. the pan would be under tension along its center line from the bridge to the neck and tail, but the sides of the pan would be less responsive.

posted evening of February first, 2020: Respond

➳ More posts about Woodworking

|  |

Wednesday, January 29th, 2020

An issue in designing the brass viola, is what to use for a tailpiece. I cannot use a cello tailpiece, because the distance from the tail to the bridge is too short. My impulse is to use a viola tailpiece; however a much longer tailgut is needed than what is used for a viola (and I think longer than a cello tailgut), and I believe the thickness of it will be too great to fit in the holes drilled into a viola tailpiece. In addition, viola fine-tuners will not work because they are too small to accept cello strings.

My tentative plan is to use a viola tailpiece but drill new holes in it, and run a Bois d'Harmonie bass tailcord through the end of the tailpiece and around the middle; and to forego fine-tuners on the tailpiece and instead use geared pegs. I may in the end have to carve my own tailpiece but am hoping not.

Update: a genius idea from the Cello international forum on FB: In lieu a tailpiece, use two loops of kevlar thread and four brass rings -- each of the strings effectively gets its own "tailpiece".

posted afternoon of January 29th, 2020: Respond

|  |

Sunday, January 26th, 2020

I want to lay out how I came to the point where I'm about to start making and putting together the brass viola. I will readily admit here that I'm hoping the project will be a success; that the instrument will sound, in the end, like an instrument. I'm pretty optimistic right now, not having begun yet to layout any parts, except on paper. (And if it comes out the other way, please read this charitably, or don't bother.)

I think of the #tincancello as being a "banjo", in the sense that the steel soundboard functions as a flexible membrane taught between the bridge feet and the rigid rim of the washtub. (For a wooden cello the rigid element is the arched woundboard itself.)

It seems to me, and I intend to verify, that it will be interesting to build a metal soundboard instrument with a soundboard that's arched and rigid-- it occurred to me several months ago that a wok could work for that. I will make a wooden neck and dowel using a roughly similar layout as the #tincancello . (The principal difference here is that the dowel will run through the very rim of the wok, instead of through the middle of the washtub.) I will also carve an arched back. My hunch is that this will produce an ideal resonating chamber.

Bracing as appropriate at the point where the neck meets the body and where the tail meets the body will allow the soundboard to resonate completely free of the tension of the strings. I'm hoping the brass will ring like a bell under these condition; and I'm making a primary assumption, that the pan will be light enough, and rigid enough, for the vibration of the bridge to really transfer to it. This is the primary factor that will determine the success or failure of the project. (Analogy to the #tincancello soundboard is not worthwhile for the reasons outlined above.)

↻...done

posted morning of January 26th, 2020: 1 response

|  |

Saturday, January 25th, 2020

Last night it occurred to me (still waiting on delivery of the pan that will be the body of the brass viol) -- I've been thinking of this instrument all along as having a dowel through the body, similar to the other instruments I've built. But if the pan is rigid and strong, it might make more sense to have a separate neck and tail, attached to the pan with bolts. I think this would offer a few key advantages:

- The resonating chamber would be hollow, like a violin's. It seems intuitively like this would produce a clearer tone.

- The joinery would be more straightforward. It will be easier to line up and drill holes in the pan, than to lay out and cut mortises for the dowel.

- The shape of the tail would no longer be limited to an extension of the dowel. I could give the tail height, so the tailpiece would attach closer to the height of the bridge feet. Then the string angle would not be so sharp on the tail side.

(Update: nm, this was a silly idea. The instrument pictured would sound horrible if indeed it would tension up at all.)

posted morning of January 25th, 2020: 3 responses

|  |

Monday, January 20th, 2020

Getting the correct string angle across the bridge is going to be really critical to laying out this instrument. The angle to the tailpiece looks like it will be pretty sharp, from my drawings. I will probably need to lower the bridge aomewhat -- indeed I may go back to the idea of using a viola bridge instead of da gamba. But I really need to see the pan to know, for now I am just guessing. Waiting impatiently on delivery.

The strings should cross the bridge at 153°. Possibly a few degrees sharper, the metal pan as I'm picturing it could stand a fairly strong tension. So that's around 77° on each side from the axis that's the bridge. I think I can make the bridge tilt back some by moving it back on the face of the pan, that will even up the angles.

posted evening of January 20th, 2020: 2 responses

|  |

|

Starting out... will add specs as I calculate them. For reference, Alan Goldblatt's cello specs.

viola d'ottone/ viola.1/ the tenor brass viola

| scale length | 535 | mm | (using ¼ size cello strings) |

| fingerboard length | 490 | mm | (on treble side -- cut away 25mm toward bass) |

| fingerboard width (nut) | 28 | mm |

| fingerboard width (end) | 60 | mm |

| fingerboard height at edge | 6 | mm |

| fingerboard radius | 70 | mm |

| dowel height | 3/4 | in |

| neck angle from vertical | 83 | ° |

| shoulder location | 110

60 | mm

mm | back from heel

above heel |

| neck length under fingerboard | 250 | mm |

neck blank 8/4

(maybe could use 6/4) | 28

7 | in

in | long

wide |

posted evening of January 20th, 2020: Respond

| Previous posts about viola d'ottone

Archives  | |

|

Drop me a line! or, sign my Guestbook.

•

Check out Ellen's writing at Patch.com.

| |