|

|

Saturday, September first, 2018

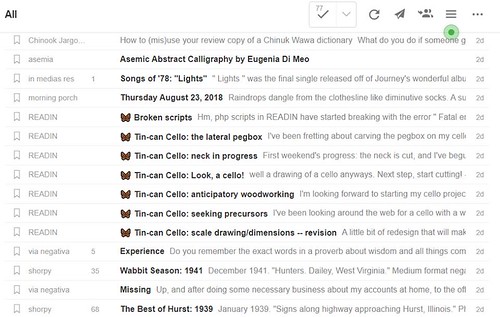

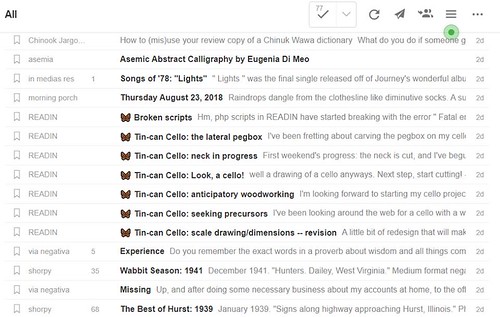

The cello's neck is for the most part (excluding the very bottom, next to where it will meet the bucket) sanded smooth to 80 grit. The dowel is straight. Today I am looking to do the rough fit to the bucket; assuming (fingers crossed!) this works, I'll be refining the fit over the weekend, and then: - Finish sanding the neck and scroll, to 320 grit.

- Color the neck and scroll.

- Finish the neck, scroll, and dowel.

- Glue up the fingerboard and nut.

- ...Setup time!

I've started marking up the bucket.

...et voici! Rough cut:

posted morning of September first, 2018: Respond

➳ More posts about The Tin-can Cello

|  |

Sunday, August 26th, 2018

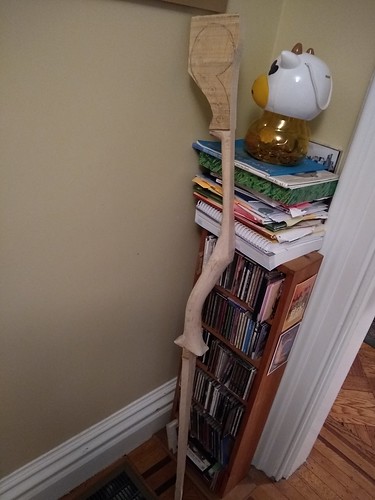

This hard maple is making me understand flatness in a whole new way. I'm not sure I've ever properly flattened a board. I'm not sure if other woods than maple can even get this flat!

posted afternoon of August 26th, 2018: Respond

|  |

|

The parts of the tin-can cello's body (excluding the bucket and all of the components; just talking about the wooden body pictured above) are as follows, from top to bottom, with rough length of each part:

- Scroll and pegbox (9")

- Neck (the part the fingerboard attaches to) (13")

- Curve (11 ½")

- Dowel (27")

I have been working this afternoon on finalizing the curved portion of the neck. I noticed last night, running my hand along the curve, that there were some bulges and hollows -- this afternoon I've been endeavoring to smooth that out, using the rasp I bought from StewMac, which I must say is one of the nicest hand tools I've encountered. Then I went over it with 80-grit sandpaper, and it's looking nice. I think I'm about to the point with Scroll, Neck and Curve, that I can start sanding with finer grits.

The curve has been interesting because I have no template whatsoever for it. I layed out the position of the upper neck using the fingerboard as a reference, and then I layed out the curve based on what I thought would look nice and would be strong.

Getting the upper portion of the neck straight and flat has been a while coming. I did a bad job of roughing it out on the bandsaw; I did not tighten the table trunnions sufficiently before I started, and the table moved out of square slightly. So the surface of it was skew. I wasn't able to get much of anywhere squaring it with jointer plane, in part because the scroll rises above the plane of the neck (nonstandard) and in part because the wood is so hard it's just very difficult to plane. I ended up flattening the surface with rasp and coarse sandpaper, checking my progress as I went against the fingerboard that I'll be gluing on there; and it took a while. But I reckon it is right, now; when I lay the fingerboard on there it lies flat and I can sight straight along it to the point of the dowel. Next I will sand it with 100- and 120-grit, to prepare for gluing. I won't glue the fingerboard on until after I have fit the body into the bucket.

posted afternoon of August 26th, 2018: Respond

|  |

Saturday, August 25th, 2018

READIN rss feed is a going concern once more! Onward...

posted evening of August 25th, 2018: Respond

➳ More posts about The site

|  |

Tuesday, August 21st, 2018

Hm, php scripts in READIN have started breaking with the error "Fatal error: Uncaught Error: Call to undefined function mysql_connect()". So far it is not affecting the blog itself, but ancilliary scripts that are called by cron jobs, like the RSS feed generator and the header quotes builder. Looks like mysql_connect is deprecated and I need to update to mysqli_connect(), and maybe update the rest of my mysql calls as well.

posted evening of August 21st, 2018: 1 response

➳ More posts about Programming Projects

|  |

|

I've been fretting about carving the pegbox on my cello... Today I had an idea for how to hugely simplify the process. I can't swear it is a good idea, but I went ahead and acted on it. Won't know until setup time if it's a boon or a bust.

The lateral* pegbox

So the idea is, instead of having two ⅜" cheeks for the peg to enter and exit, with the string winding in the middle, there is just a central fin ¾" wide. Pegs enter from alternating sides; the string winds on the opposite side to where the peg enters.

The good

It looks kind of cool; it's original; it's way simpler to make. Also: if I ever wanted to switch to 5 strings, easy to drill another peghole.

The bad

I'm not certain about the physics here. In a traditional pegbox, the stress on the string is in between two points of support; here, the stress will be supported on one side only. This may break the peg, I'm not sure how strong they are. We'll see! If I'm wrong and it does not work, I'll need to carve a new pegbox and scroll, and graft it onto the neck. (Or as Jeff points out, if the pegs don't work I could try using bass viol tuning machines as a fallback option.)

but

Here's why I'm sort of confident about the peg holding up: if the string is wound properly, the stress on the peg will be right next to where it emerges from the supporting wood. This seems like a pretty strong load-bearing point.

*(and note)

Not a huge amount of thought went into the nomenclature. If you've got a more descriptive adjective for this than "lateral", please let me know.

↻...done

posted evening of August 21st, 2018: 2 responses

➳ More posts about Luthery

|  |

Monday, August 20th, 2018

First weekend's progress: the neck is cut, and I've begun shaping it. (A key realization was that I'm going to need to get an angle grinder for cutting the metal tub, I ought to get it now so I can use it in shaping the neck. That cut many hours off of the time to shape the neck.) The upper surface is not precisely level or flat, and it is slightly wider than it needs to be. I'm going to spend my spare time over the next few days truing that up with rasp and scraper, and getting it to fit the fingerboard. Then I will work on the scroll and pegbox.

posted morning of August 20th, 2018: Respond

|  |

Saturday, August 18th, 2018

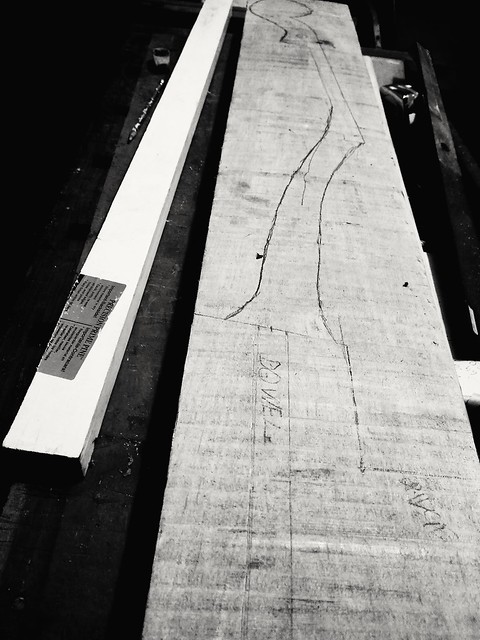

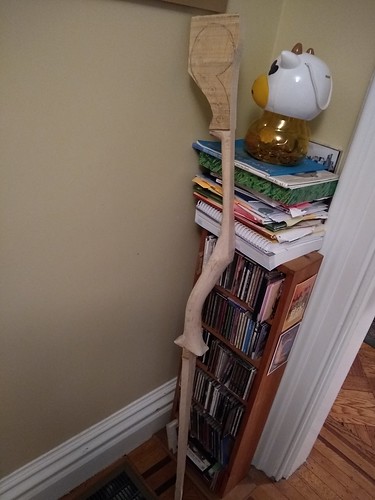

well a drawing of a cello anyways. Next step, start cutting!

--well, the neck is a little off-center to the dowel. I think it will be stronger if it's centered.

posted afternoon of August 18th, 2018: 2 responses

|  |

Thursday, August 16th, 2018

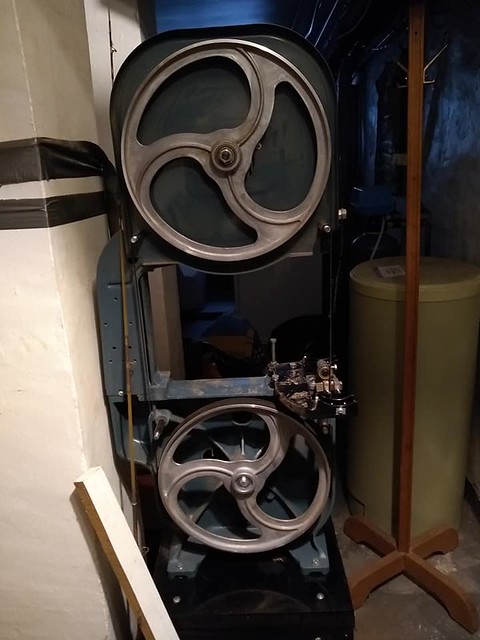

I'm looking forward to starting my cello project this weekend, and starting to get my shop in a little bit of order (anyway a marginally less chaotic state) and figure out where my tools are. I haven't done much woodworking to speak of since like 2007 at least! I'm really looking forward to having a well tuned up bandsaw, and to learning how to tune it up. This evening I found a box of rasps and files that I haven't seen in years :).

posted evening of August 16th, 2018: Respond

|  |

Tuesday, August 14th, 2018

I've been looking around the web for a cello with a washtub body... Haven't found one yet quite like what I'm making, but there are a lot of different takes on the idea...

- A washtub cello with a plywood soundboard, seen at the 8th NYC Musical Saw Festival.

- A bucket cello made by Joe Rauen, with a long bridge connecting the strings to the back of the instrument.

- A tin can cello busking in France.

- A couple of washtub basses with strings and bridge, some with a soundboard added to the front of the tub, some using the back of the tub as soundboard.

- Paul Snider's junk orchestra includes the trashcan cello pictured above.

posted evening of August 14th, 2018: 4 responses

| Previous posts about Projects

Archives  | |

|

Drop me a line! or, sign my Guestbook.

•

Check out Ellen's writing at Patch.com.

| |